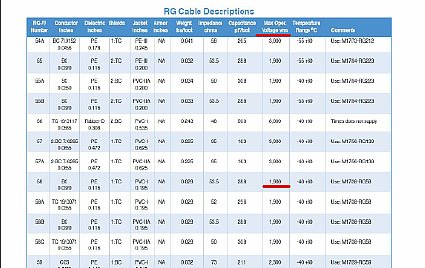

|

K4CHE GO-9 HF/MF Transmitter Project: HIGH VOLTAGE SUPPLY |

|

A Saga of sorts. My construction techniques for a High Voltage Supply for the GO-9 Transmitter.

I had constructed most of the power components for my GO-9 Rectifier on flat trays for ease of maintenance and to allow easy insertion and removal from the main chassis of the Rectifier. The previous owner of the Rectifier assembly had stripped out most of the components so a major power supply and control constructing project was necessary. I continued the tray construction technique with the the High Voltage Supply.

.jpg)

A simple discharge stick. Use wood, high voltage cable, a good quality alligator clip and a simple tip from #12 wire.

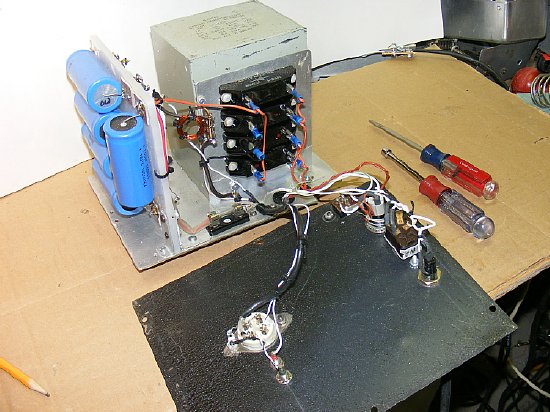

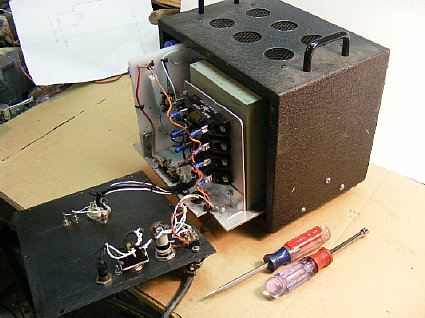

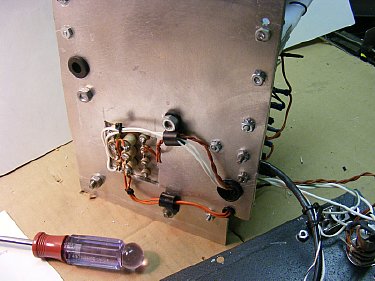

The high voltage tray mounts inside a "Bud" cabinet and is help by clamps fabricated from 3/4 inch right angle aluminum. A single thumb screw and bolt hold each clamp in place.

My HV supply utilizes

a standard bridge configuration and a capacitor input filter.

Click to Enlarge

Click to Enlarge

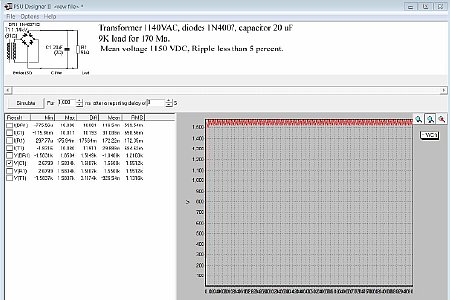

" Power

Supply Designer" simulation came right out on the money with bench

testing after construction. This is easy to use software available at

no cost and is perfect when you want to try out different power supply

components and ask "What If"? In this case my transformer

output was 1140VAC, a bridge rectifier, a capacitor input filter of 20

uF and my load simulation for 170 Ma was 9000 ohms. The diodes that were

used for the simulation were 1N4007X2. The standard maximum ripple voltage

for years for a "code or CW transmitter" has been 5 percent.

We were at .045 on the ripple - - close enough for government work and

this allowed us to keep the parts count down (no choke etc.) in the high

voltage supply and make everything fit. You can add a choke prior to

the capicator to reduce the ripple slightly but be prepared for a drop

of 400 to 500 volts. Based on the above "simulation" I pressed

on with construction with just the capicator input filter.

Power Supply Designer Program is available at the "Duncan Amp" pages. "PSU Designer II is designed to help you with the design of simple linear (unregulated) mains power supplies, as often found in tube amplifiers." The simulation software also includes Tube type rectifiers such as a 5R4, 5Y3 etc.

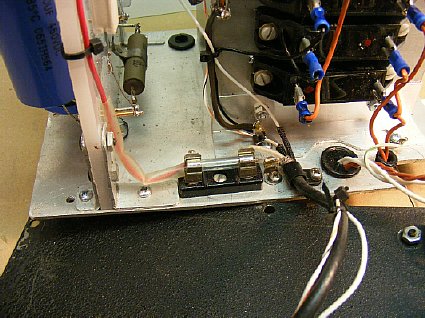

The

tray slides out for easy maintenance. The 100uF caps are shown soldered

to the small "islands" of copper clad PC board which are attached

to the lexan. The 450 volt capacitors are in series and are 100 uF each.

A total of 5 capacitors resulted in total of 20uF.

Since I needed

a bleeder resistor I choose to use 5- 20K power resistors which provided

voltage equalization for each capacitor. On smaller power supplies I often

omit equalization resistors when putting capacitors in series if the rated

voltage for the capacitor is not exceeded.

The Diode Bridge uses K2AW's famous diode blocks. Sadly to say they are no longer available from K2AW but a search on ePay for "high voltage diode block" or "high voltage diode" will provide you with other choices.

These diode blocks are pretty rugged, I did not use the traditional 10 ohm surge resistor in each output lead of the transformer prior to the diode blocks for surge protection.

The master switch is safety wired to the "On" position as the GO-9 Rectifier Panel will provide control. Drill a hole in the bat handle of the switch to accommodate the "safety wire".

Click to enlarge

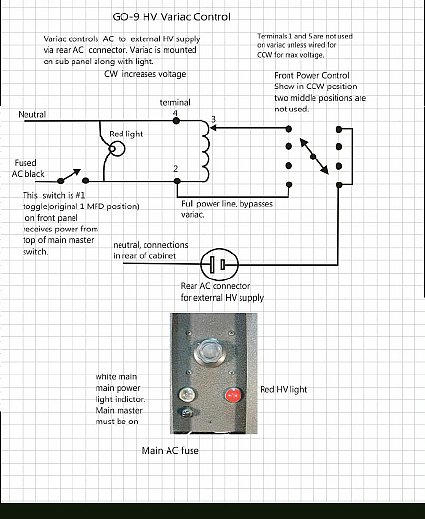

Click to enlarge A variac on the GO-9 rectifier panel provides control of the high voltage for adjustable transmitter power levels. The HV supply provides 1800 volts no load and 1550 volts when the transmitter is loaded to 175 Ma.

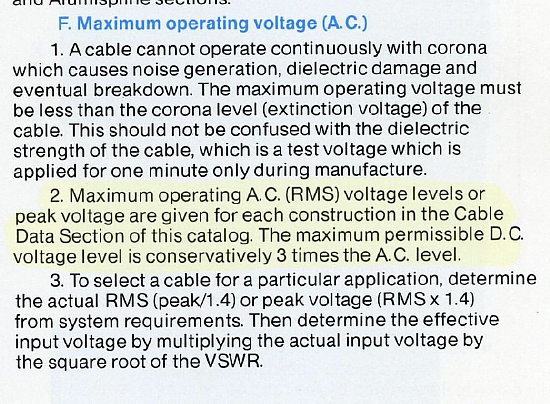

With my working voltage of 1550

VDC I used a ceramic socket and standard four pin plug.

The cable is constructed from a good quality

RG-58. One of the pins is used for the HV and two of the other pins are

used for the ground (shield). The green and red tip jacks are used for

test metering. The green is for current via a meter shunt in the minus

lead and the red is for voltage via a 47K resistor tied into the last

bleeder resistor.

Good quality RG-58 is an excellent choice for the HV cable. Leave the shield intact for safety and for the ground.

It all fits.

The mounting "islands" made of copper clad PC board mount to the lexan board using small screws.

"

One

inch pieces of #12 wire extend through the lexan and serve as soldering

posts on the other side for the resistors. Note the fuse which is located

in the B plus output line. I use a 1/2 amp. The fuse is not "rated

for high voltage but when the B plus is accidentally shorted it will blow

and the link will vaporize. The fuse is installed to protect the diodes

blocks.

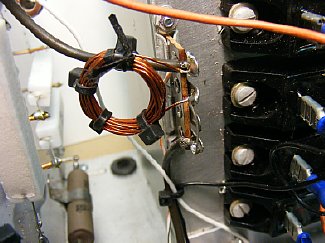

A small

meter shunt was installed in the minus side of the power supply to provide

external metering via a test jack on the front of the panel.

The tray is mounted on brackets in side the Bud case and the wiring on the bottom of the tray is well above the bottom of the case. Note the feed through grommets.

The "Bud" cabinet has a width of 10 inches, height is 8 inches and depth is 7. Handles were attached and 1 1/4 inches cooling holes were cut in the top. ePay is a good source of cabinets.

The

RG-58 shield is the B minus return and ground. An extra "safety"

ground wire was attached directly to the tray.

The small HV supply fits easily on my GO-9 accessory shelf. The white light below the switch is redundant as there is a "HV" ON light on the GO-9 Rectifier panel.